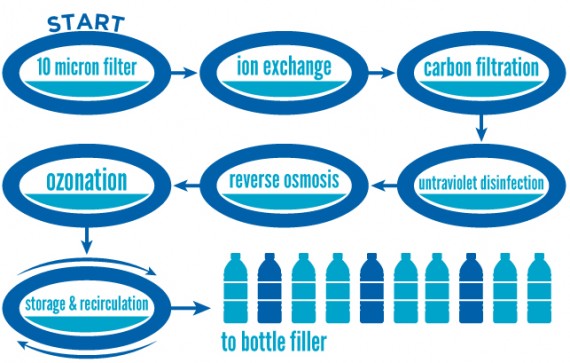

DMCW’s Water Purification Process

A great looking water bottle customized with your logo or design is just one reason to choose DrinkMore Custom Water for your customized water bottles. The other reason is our purified water.

All of our bottled water—including our customized water bottles—goes through our custom-engineered, water purification process:

The following is a detailed description of each of the steps in our water purification process.

1. Sediment Filter

Our complex purification process begins with a simple, pleated-paper sediment filter. This filter traps relatively large particles which may be present in the water-things like dirt, sand, slime and grit. It’s necessary to start the process with this basic step in order to remove these large particles which could foul or clog the more sensitive equipment used at later stages.

Our initial sediment filter is rated at 10 microns (a micron is one-millionth of a meter, or 1/25,000th of an inch.) How small is that? Well, the human eye can only see particles 20 microns in diameter or larger. You’d be very surprised at what we see when we change these filters.

2. Ion Exchange

The next step is the removal of various metallic elements through a process known as ion exchange. Sometimes referred to as water “softening,” ion exchange utilizes large tanks which are filled with a special, negatively-charged resin. The resin serves as a reservoir for large numbers of positively charged sodium and potassium ions.

As water passes through the ion exchange system, metallic ions, which carry a strong positive charge, displace the more weakly charged sodium and potassium ions. The metallic ions are thus trapped via electromagnetic attraction to the resin particles. The ion exchange beds are then automatically cleansed and regenerated at prescribed intervals based on water volume.

Ion exchange provides highly effective removal of the metals responsible for pipe scaling and deposits. The process also removes various heavy metals, such as lead, mercury, iron, and cadmium, which have been associated with well-publicized health concerns.

From DrinkMore Water’s perspective, it is important to remove metals early in the purification process to protect the more sensitive technology used in later steps, since high levels of metals can damage this equipment.

3. Activated Carbon

Once the water passes through the ion exchange system, it moves into an oversized granular activated carbon bed. Carbon filtration (also known as charcoal filtration), which utilizes a process known as adsorption, is a particularly effective technique for chlorine removal. Pesticides, herbicides, and other organic contaminants (especially volatile organics) are also removed at this stage.

Carbon also does an excellent job of removing trihalomethanes (THMs) from the water. THMs are a class of chemicals which result from the interaction of chlorine and decaying organic matter in the public water supply. These chemicals are known carcinogens, and the high levels found in local water supplies have been a cause for concern in recent years.

4. Ultraviolet Disinfection

Since the DrinkMore Water process removes all chlorine from the water, two forms of chemical-free disinfection technology are employed to ensure that the purified water remains absolutely and completely free from any sort of microbiological contamination. Ultraviolet disinfection is the first of these technologies.

At this step of the process, the water passes through a special chamber which houses a large ultraviolet light source. This ultraviolet light acts as a powerful sterilizing agent. If any bacteria, viruses, or other microbiological contaminants are present in the water, the ultraviolet light at this particular wavelength destroys the genetic material within these organisms, eliminating the possibility of bacterial or viral reproduction and proliferation. The organisms quickly die and are captured and removed during the reverse osmosis purification process.

5. Reverse Osmosis

Reverse osmosis is the centerpiece of the DrinkMore Custom Water purification process.

In reverse osmosis, high pressure is used to force water across a membrane while impurities are left behind. In other words, the high pressure causes the impurities to become more concentrated on one side of the membrane. Only the pure water is able to cross the membrane; even the dissolved impurities which cannot be removed by conventional filtration are captured and eliminated by DrinkMore Custom Water’s reverse osmosis purification system.

The reverse osmosis system featured at DrinkMore Custom Water utilizes state-of-the-art technology for both purified water production and quality control. Every drop of our purified water must pass through approximately twenty layers of reverse osmosis membranes.

If even a slight variation in quality occurs, an alarm is triggered and the entire system shuts down. The result is a purity level that’s second to none. We bottle at a purity of 1.2 parts per million total dissolved solids. In fact, we encourage you to compare our water with any other water-spring water, mineral water, or filtered water.

6. Ozonation

The second phase of chemical-free disinfection is known as ozonation. Ozonation relies on oxygen to ensure that our purified water remains free of any possible microbiological contamination.

The ozonation process takes basic molecular oxygen (O2) and passes it through a special chamber in which it is exposed to a high voltage electrical charge. (This type of ozone generation is called cold-plasma discharge.) The electricity causes the oxygen molecule to split and recombine in a higher-energy form known as ozone (O3). This ozone is then continuously circulated through the purified water.

Ozone is a very powerful disinfectant and is capable of oxidizing a very broad range of contaminants. In fact, ozone is highly effective against many types of impurities and organisms, such as cryptosporidium, that are utterly impervious to chlorination. Just how powerful is ozone? First of all, it’s about 1,500 times more effective than chlorine as an oxidant.

In real life, ozone is very effective at killing cryptosporidium. Tests have shown that at normal concentration levels (1 part per million), ozone will destroy 99.99% of cryptosporidium oocysts given five minutes of contact time. Chlorine, however, doesn’t affect cryptosporidium oocyst viability at concentrations of 30,000 parts per million for a period of eighteen hours. The standard concentration of chlorine in tap water is around three parts per million-imagine what 30,000 parts per million would taste like!

Ozone is not a stable state for oxygen. It has a half-life of about 20 minutes, so by the time our bottle reaches your lips, the O3 has returned to O2.

7. Storage

After the water has passed through the preceding eight steps it moves into the storage and recirculation phase. This storage and recirculation system has been designed so that DrinkMore Water will retain its exceptionally high purity and will not come into contact with any materials or substances which could in any way compromise the quality of the water.

DrinkMore Water features a storage system made entirely of stainless steel. Many people are unaware that brass, a key component of many plumbing systems, can be a primary source of lead contamination. By using only stainless steel, this problem, and the problem of potential interactions with other substances, is completely avoided.

8. Recirculation

DrinkMore Water does not simply sit in storage after purification. Instead, the water continuously travels through a recirculation loop. In addition, the ozone levels are continuously monitored and controlled to ensure that all of our product water in storage (over 35,000 gallons at any one time) is always ready for bottling.